Mosturn Logistics Management System

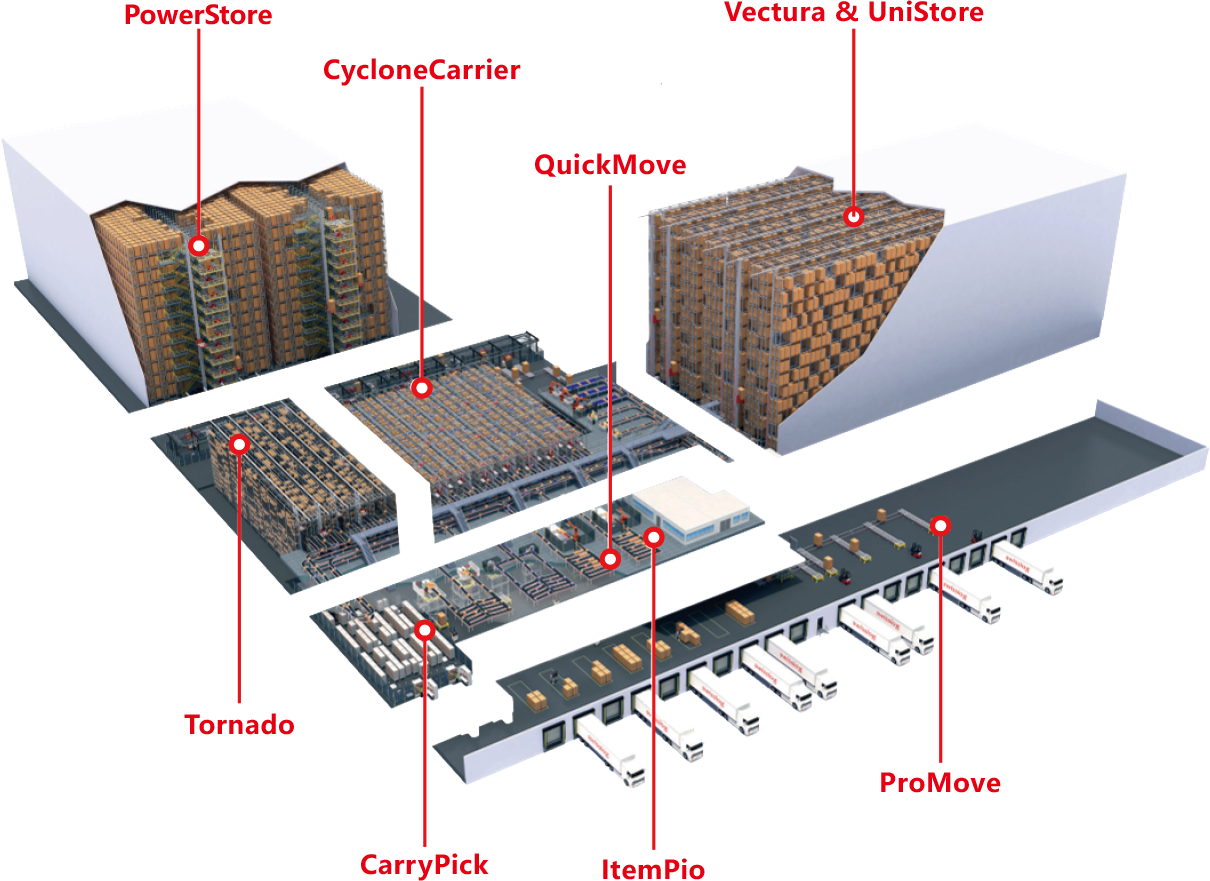

MtLms Intelligent Logistics Management System is the use of assembly or welding shelf automatic three-di- mensional warehouse system, with stacker, conveying system, computer management control system, can fully realize the available space, handling and access mechanization, storage management modernization. High storage rate, convenient, automation and other high-tech, can give enterprises to reduce a lot of labor, site and other costs.

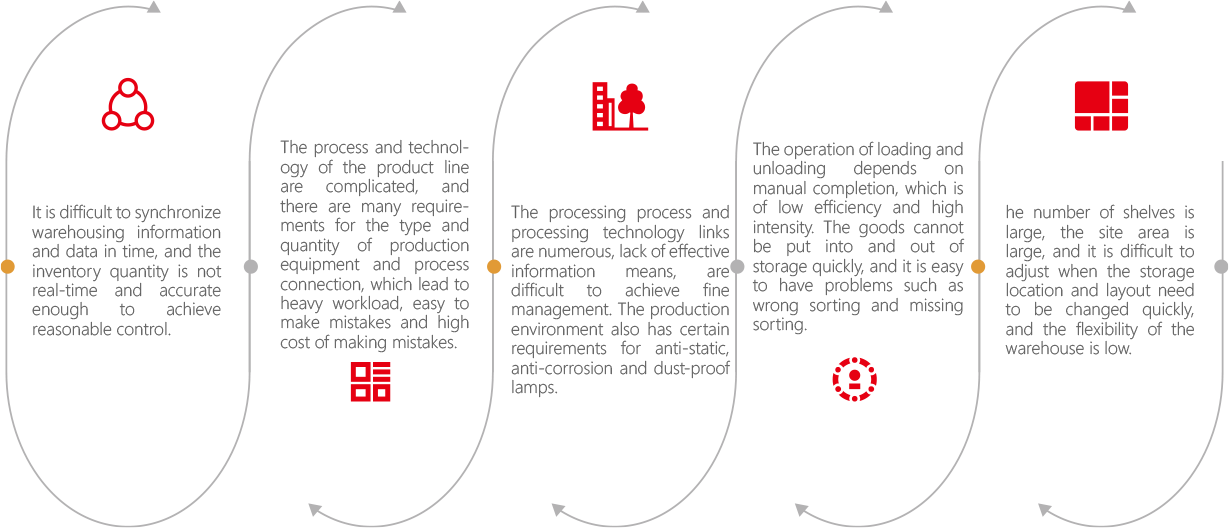

Current situation of traditional storage

Three-dimensional warehouse

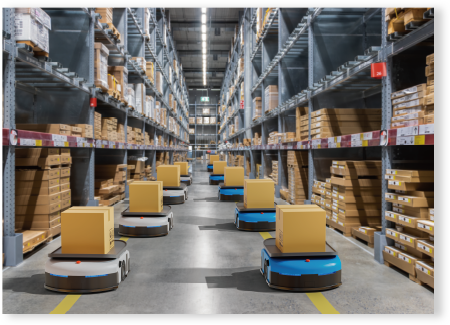

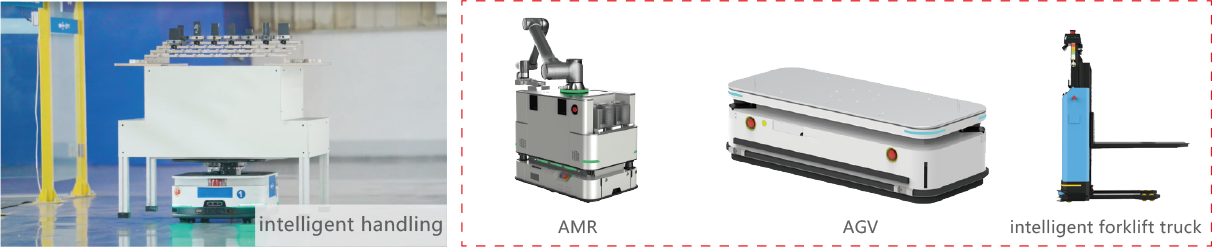

AGV management system

The system is a new generation of intelligent logistics handling robot which integrates automatic docking, automatic handling, data tracing and other functions. It provides a variety of material carrier handling solutions according to customers’ diverse scenarios, realizing the docking handling of materials to the production line and the application of online or offline sorting from shelves to workstations. The system can also flexibly deal with different containers and scenarios, solve the tedious manual handling, using machines to reduce enterprise management costs and product defect rate, improve logistics efficiency, is conducive to enterprise cost reduction and efficiency.

Advantages & Benefits

01 Optimized logistics transfer efficiency, timely and accurate distribution

- Support for large-scale road networks, allowing maximum changes to path planning and ensuring smooth logistics roads in workshops;;

- Real-time detection of path congestion level and advance dispatching of idle AGV to task points to wait, achieving task load balancing and improving overall logistics efficiency;;

- Replacing the traditional operation mode of manual driving to realize timely, efficient and ready material distribution links.。

02 High degree of automation, reducing wasted labor cost

- 24-hour operation and distribution can realize zero “peak” time for distribution, and normal shift changeover is sufficient.。

- Supporting mixed cluster operation cooperation of different types of AGV, supporting direct interaction with various types of external equipment such as elevators, hoists, air shower doors, etc., realizing control of external equipment and saving manpower;;

03 High safety and effective avoidance of danger

- Positioning of AGV forklifts, automatic obstacle avoidance, and driving according to the prescribed route to ensure the safety of goods;

- Continuous operation without accidents, reducing human fatigue and effectively avoiding safety hazards.。