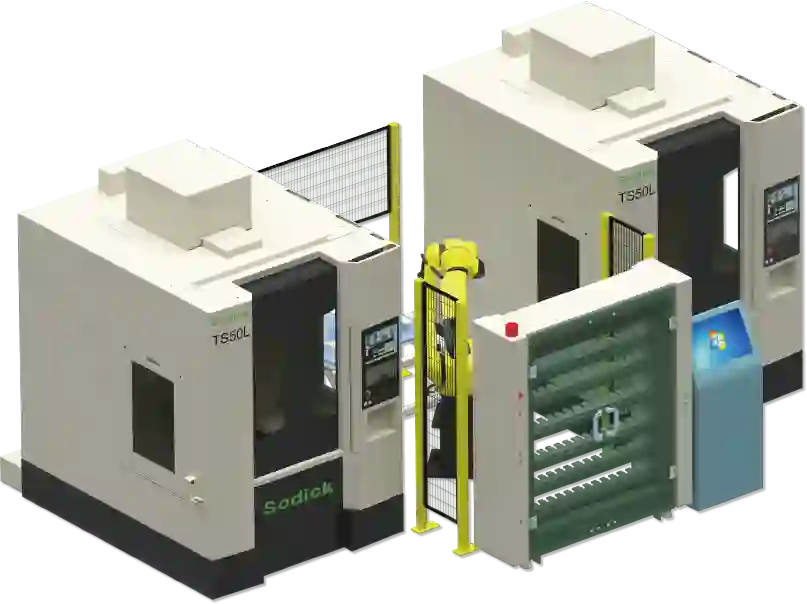

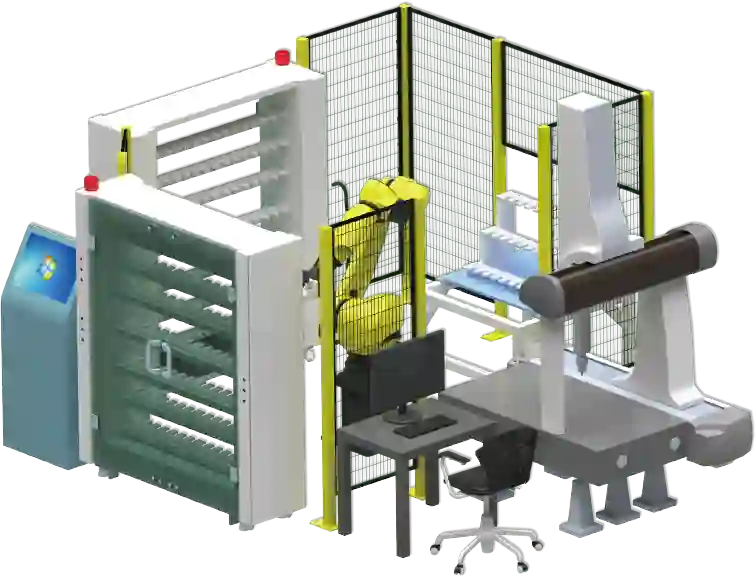

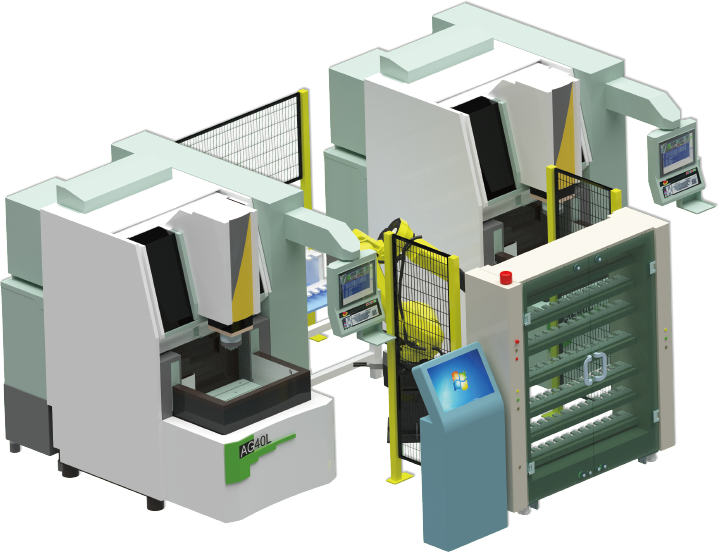

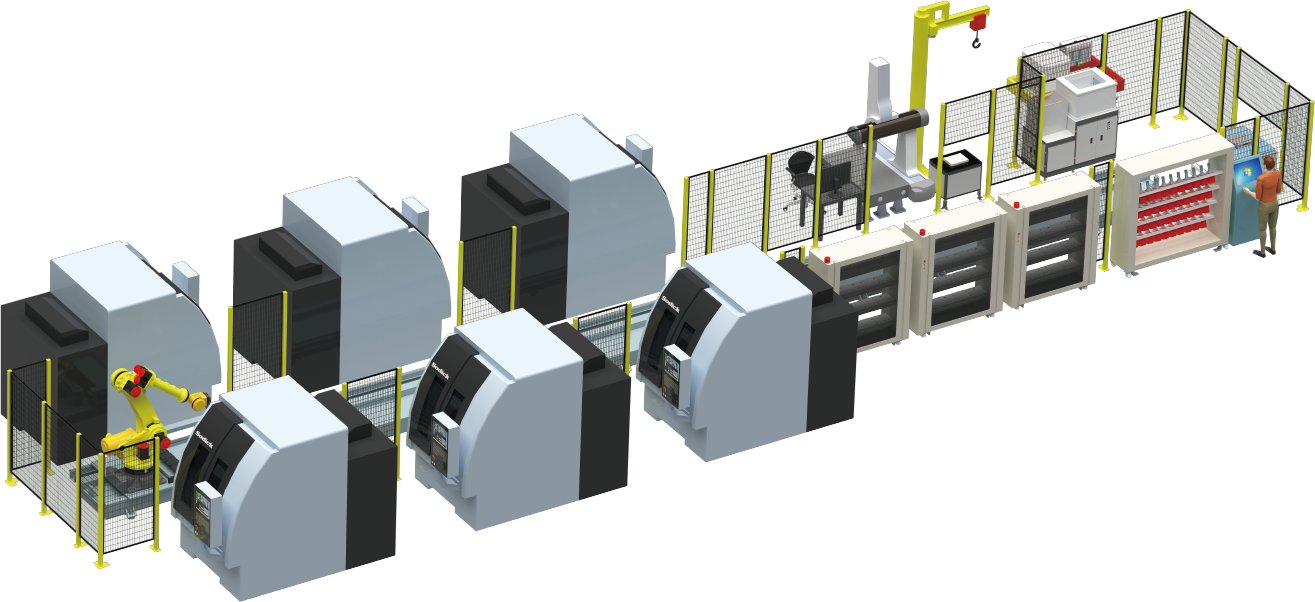

Mosturn MtFms flexible manufacturing system consists of module and hybrid mode of electrode/part CNC milling automation, electrode/part automatic inspection, EDM discharge processing automation and hybrid automation for flexible manufacturing. The system is capable of automatic production scheduling, industrial robot automatic loading and unloading, real-time data collection, OEE equipment monitoring and failure warn- ing, etc. Through self-developed automation control technology, the interconnection and integrated application between equipment, production line and information system can be achieved. The goal is to reduce the man- power on production lines, establish paperless information system, real-time data collection, discrete manufac- turing automation, and finally to achieve an unmanned, light-off factory. It helps companies to relieve the pres- sure caused by labour costs in a comprehensive and effective way, and makes coordination and communication between the various control units more flexible and convenient, thus establishing an intelligent manufacturing model with high precision, high efficiency and low cost.