The characteristics of the automobile industry mainly include diverse production modes, complex manufacturing processes, different optimization objectives of different manufacturing workshops, different production modes of different vehicle types, and complex and flexible product configuration.

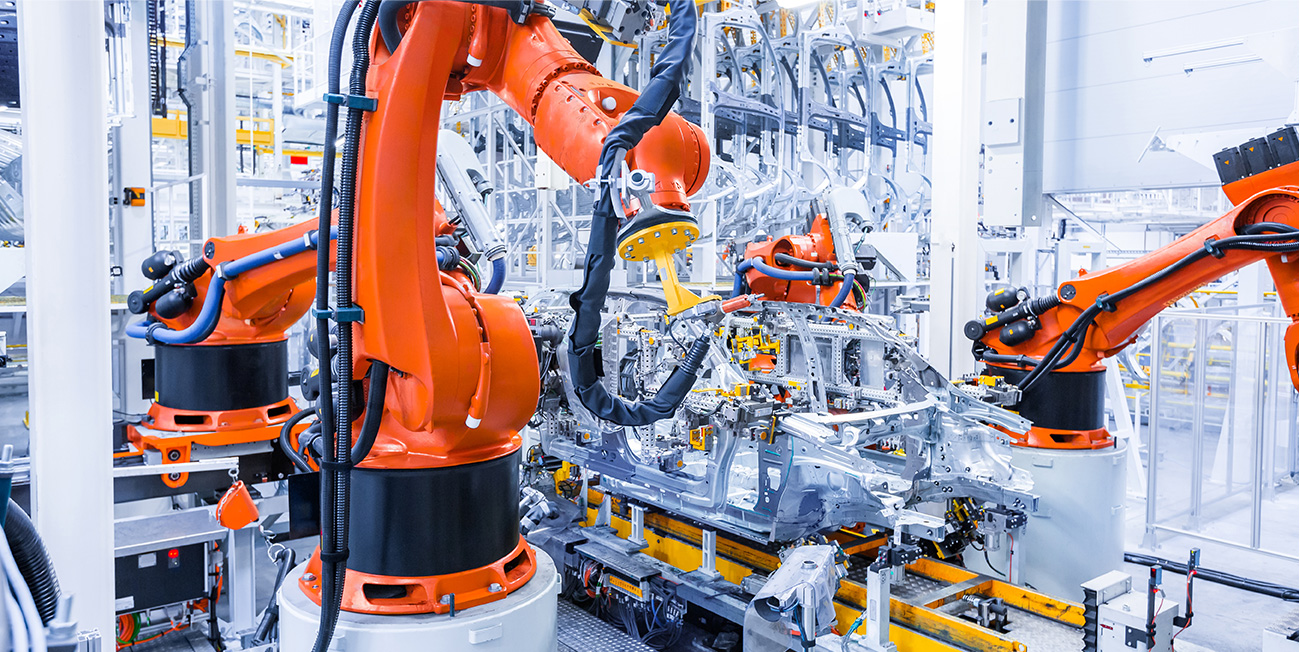

MT-MES system is a production information management system for intelligent manufacturing and execution layer of automobile digital workshop. Therefore, IT not only has the large-scale data processing function of the IT system in the era of industry 3.0, but also integrates the high-speed real-time acquisition and processing ability of the automation system in the era of industry 4.0. It can perfectly combine the automation technology with the enterprise management system. It is conducive to comprehensively improving the manufacturing level and management level of automobile enterprises, production safety, quality control, energy saving and consumption reduction, and improving the overall manufacturing level of the automobile industry.

Among the medical instruments, bone screws, sphygmomanometer, operating bed, ultrasonic instrument and so on are closely related to human health. Therefore, the manufacturing quality of the medical device industry and the safety, effectiveness and stability of the production process need to be strictly controlled. With the continuous development of the domestic medical device industry, more and more enterprises are able to export or even sell their products abroad, and the international strict industry standards have become a new challenge for many medical devices.

MT-MES is a digital management solution of production and manufacturing process with MES as the core, which can meet the needs of material management, work order management, formula management, warehouse management, equipment management, time management and so on in the whole process management system of production and manufacturing enterprises. Solutions are offered in suite form and can be combined flexibly according to enterprise production management requirements.

Manufacturers and assemblers of 3C electronic products are faced with ever-changing market demands, user experience and technical challenges, and their products are frequently upgraded. In this context, 3C electronic products are required to be more intelligent, humanized, portable, support the Internet of things and remote control, and must be efficient and innovative to attract consumers. At the same time, companies need to always be flexible and front-end, improve product quality and reduce manufacturing and administrative costs. For mass production, rapid wire change, the predictable process control, high quality and efficient and a large number of data processing are very important for enterprise management.

Based on the manufacturing cost pressure of enterprises and to meet the needs of the 3C market, we launched a one-stop solution. Complete MES+WMS+ automation software and hardware solutions meet the entire production process control in 3C electronics field, helping enterprises quickly build digital factories.

As a representative of “Made in China”, the household appliance industry is also in a critical period of development of “from large to strong”. In the current new era, according to the requirements of the 19th National Congress of the Communist Party of China, improve the quality of the supply system, create a number of well-known brands, high added value, high-quality household appliances products, promote the high-quality development of the household appliances industry, are the situation and task facing the household appliances industry. The demand of consumers for the household appliances in our country has changed from meeting basic use demand to individuation, diversification, intellectualization and high-end. In order to grasp the initiative in the new competition pattern, manufacturing upgrading has become the common choice of Chinese household appliance enterprises.