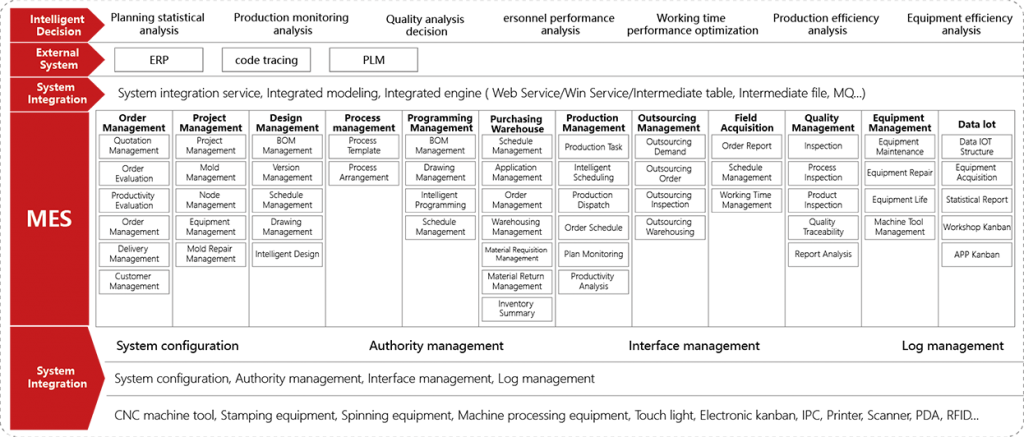

What are the functions of the MES software system?

As the global smart manufacturing continues to thrive, MES (Manufacturing Execution System) software system, as an integral part of digital factories, has brought production management to a whole new level. Together with Mosturn Intelligent Technology, let’s explore the digital future and usher in a new era of intelligent manufacturing.

1. Automated Production Process Control

The MES software system enables automated control of the production process through data collection, analysis, and processing. Real-time data from the production site is collected and transmitted to the MES system, providing comprehensive production information for management personnel to make timely decisions and improve efficiency and quality.

2. Real-time Production Monitoring and Traceability

MES software system can monitor the operation status of each section of the production line in real-time, promptly detect and handle issues to ensure smooth production processes. Additionally, the system enables production traceability, providing historical records of production data for analysis and problem tracing.

3. Resource Scheduling and Optimization Enhancement

With the resource scheduling function of the MES software system, enterprises can allocate and optimize production resources based on real-time data to avoid wastage and improve productivity. The system’s optimization algorithms also enable intelligent adjustment of production plans, preventing issues caused by insufficient or surplus resources.

4. Product Quality Management and Continuous Improvement

The MES software system facilitates product quality management and continuous improvement through comprehensive process monitoring and data analysis. The system collects and analyzes quality data in real-time, providing feedback and adjustments to enhance product quality and meet customer demands.

5. Supply Chain Collaboration and Coordination

By integrating with the supply chain system, the MES software system achieves efficient collaboration between production and the supply chain. Enterprises can obtain real-time information from the supply chain system, enabling timely production adjustments and arrangements to ensure smooth supply chain operations, reduce inventory pressure, and improve production flexibility.

6. Intelligent Data Analysis and Forecasting

The MES software system integrates advanced data analysis algorithms and artificial intelligence technology, enabling intelligent analysis and forecasting of production data. Through the system’s analysis of extensive data, enterprises can promptly identify potential production issues and make corresponding adjustments for continuous improvement and optimization.

As the core system of digital factories, the MES software system has become a vital foundation for intelligent manufacturing. It is our hope that by introducing the functions of the MES software system in this article, enterprises can gain a deeper understanding and application of MES systems, improve production efficiency, reduce costs, and realize the dream of intelligent manufacturing. Let’s join hands and embark on a journey to usher in a new era of intelligent manufacturing!